Provide customers with professional, franchised, dedicated and comprehensive services

To be one of the "Most Influential Enterprises in China's Adhesive Tape Industry"

Hotline:

+86-18082341928

To be one of the "Most Influential Enterprises in China's Adhesive Tape Industry"

Hotline:

+86-18082341928

VHB is the abbreviation of Very High Bond, which means super-adhesive Double-sided adhesive, which is the advanced, professional Double-sided adhesive tape on the market.

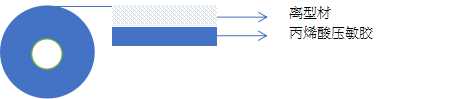

The company's Double-sided Non-Backing Acrylic foam adhesive tape, which is made by the exclusive Korean technology research and development of Acrylic, has a structural strength of more than five times that of ordinary foam. It is sealed and foamed, and each bubble is independent of each other. It can effectively block water vapor and achieve watertight and airtight effect.

In 2015, the company introduced the first Acrylic VHB adhesive tape production line from abroad. There are black, white, gray, transparent and other colors, the thickness is from 0.05 to 3mm, and there are nearly one hundred kinds of products.

In 2015, the company registered the “SHYQ” trademark to create a professional Acrylic VHB adhesive tape production brand.

1, the automotive industry: all kinds of cars, commercial vehicles, trucks and construction machinery business travel assembly and decoration;

2, the electronics industry: a variety of electronic digital products, home appliances adhesive fixed processing and assembly, sealed, waterproof;

3, Advertising industry: various advertisements, road signs, logo industry, etc.;

4, Construction industry: Provide super-adhesive strength and dust-proof sealing for glass curtain wall, door and window assembly, elevator, etc., and provide insulation and connection for building construction. Bundling, waterproofing, repairing, sealing, etc.

| Serial number | Product Model | colour | Thickness (mm) | Temperature resistance (°C) | 180° peel strength (gf/25mm) |

80 ° C retention (h) |

| 1 | Y9025G | gray | 0.25 | -40/+120 | 2000 | >24 |

| 2 | Y9040G | gray | 0.40 | -40/+120 | 3300 | >24 |

| 3 | Y9064G | gray | 0.64 | -40/+120 | 3500 | >24 |

| 4 | Y9080G | gray | 0.80 | -40/+120 | 3700 | >24 |

| 5 | Y9120G | gray | 1.20 | -40/+120 | 3500 | >24 |

| 6 | Y9150G | gray | 1.50 | -40/+120 | 3500 | >24 |

| 7 | Y9200G | gray | 2.00 | -40/+120 | 3500 | >24 |

| 8 | Y9300G | gray | 3.00 | -40/+120 | 3800 | >24 |

| 9 | Y9025W | White | 0.25 | -40/+120 | 2800 | >24 |

| 10 | Y9040W | White | 0.40 | -40/+120 | 3000 | >24 |

| 11 | Y9064W | White | 0.64 | -40/+120 | 3200 | >24 |

| 12 | Y9080W | White | 0.80 | -40/+120 | 3300 | >24 |

| 13 | Y9120W | White | 1.20 | -40/+120 | 3500 | >24 |

| 14 | YQ7200W | White | 2.00 | -40/+120 | 3000 | >24 |

| 15 | Y9020B | black | 0.20 | -40/+120 | 2000 | >24 |

| 16 | Y9040B | black | 0.40 | -40/+120 | 2500 | >24 |

| 17 | Y9064B | black | 0.64 | -40/+120 | 3200 | >24 |

| 18 | Y9080B | black | 0.80 | -40/+120 | 3500 | >24 |

| 19 | Y9120B | black | 1.20 | -40/+120 | 3800 | >24 |

| 20 | Y9150B | black | 1.50 | -40/+120 | 3200 | >24 |

| twenty one | Y9025C | Transparent | 0.25 | -40/+120 | 2800 | >24 |

| twenty two | Y9050C | Transparent | 0.50 | -40/+120 | 3000 | >24 |

| twenty three | Y9080C | Transparent | 0.80 | -40/+120 | 3200 | >24 |

| twenty four | Y9150C | Transparent | 1.50 | -40/+120 | 3600 | >24 |

| 25 | Y9200C | Transparent | 2.00 | -40/+120 | 3800 | >24 |

| ★ Note: The above results are representative values detected by the company according to the standard test method, not guaranteed values. | ||||||

Go

Top